TechCenter

Experience innovation live –

at the new TechCenter

Our TechCenter is not a showroom – it´s a place where the future takes shape.

Here, innovation becomes visible, audible, and tangible. We bring ideas to life, test technologies under real operating conditions, and develop solutions together with our customers – individual, practical, and effective.

In the new TechCenter, we create space for genuine exchange, joint development, and measurable results. Under real conditions, we test materials, analyze processes, and optimize systems – turning every idea into tangible success.

What makes it special: our systems can be flexibly adapted to a wide variety of materials and requirements.This allows us to generate real performance data, giving our customers the confidence to make the right decisions for their processes and investments.

And the best part: you’re right in the middle of it.

Experience live how your material runs on our machines, how data is created, and how insights turn into progress for your project. Together with our experts, we develop customized solutions that show what modern recycling technology can achieve – precise, efficient, and sustainable.

We turn technology into trust!

Practical results for informed decisions

Flexible system concepts for every application

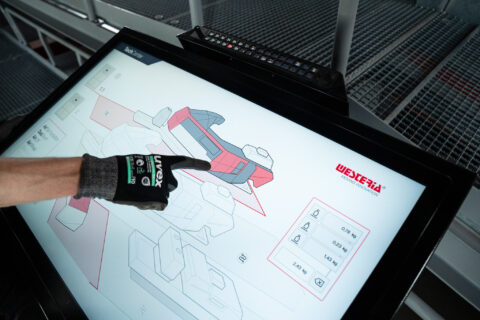

Measurable performance in real time

Technical support from our experts

Solutions that make a difference

“Proof before you buy” – That is precisely what matters most to our customers in a highly competitive market.

Experience material analysis live

Full control for maximum transparency

Three lines. Countless possibilities.

MultiFeeder

More information

ChainCon

More information

FlatCon

More information

Line 1

AirStar evolution

More information

AirLift with AirWheel

More information

Line 2

AirStar evolution DuoDrum

With its integrated DiscSpreader, it delivers perfectly balanced material distribution and enables precise three-fraction separation across a 1,500 mm working width – setting new standards for efficiency, performance and purity of results.

More information

DiscSpreader

More information

Line 3

DiscSpreader automove

More information

AirLift mit AirWheel

More information

Voices from the Industry