Particularly precise sorting thanks to AirLift

AirLift AirLift AirLift

Westeria Airlift enables sorting of plastic fractions

Air classifiers are a key element in systems for separating the components of differing weights present in waste streams. Westeria’s AirLift is particularly selective. A separator for ultra-lightweight materials, it is now even capable of sorting plastics fractions made up of components differing only slightly in specific weight. Example applications include PET bottle recycling, in which the valuable PET fraction can be highly efficiently and cleanly separated from lightweight contaminants such as PE film or paper labels.

The regulations governing plastics products are increasingly requiring the use of larger proportions of recycled materials. Germany’s Packaging Act specifies a material recycling rate of 58.5% for plastics packaging, a rate which is set to rise to 63% from 2022. While these requirements disregard economic factors, the oversupply of plastic scrap and the current, greatly reduced prices for virgin plastics mean that the requirements on the quality, i.e. purity, of the input available for recycling are increasing. As a result, greater attention has to be paid to the processing step upstream of recycling, namely sorting, if much greater quantities of material which can be put to renewed material use are ultimately also to be obtained from post-consumer waste.

New market situation demands the right tools for the job

Conventional over-conveyor extractors or also air classifiers, as for example used in composting plants, are very well suited to separating different weight fractions in waste streams. They cannot cope, however, when it comes to differentiating presorted or similar lightweight components. This is where the AirLift comes in. It can also replace conventional air classifiers in existing installations where it can then for example separate plastics film from paper or different plastics from one another.

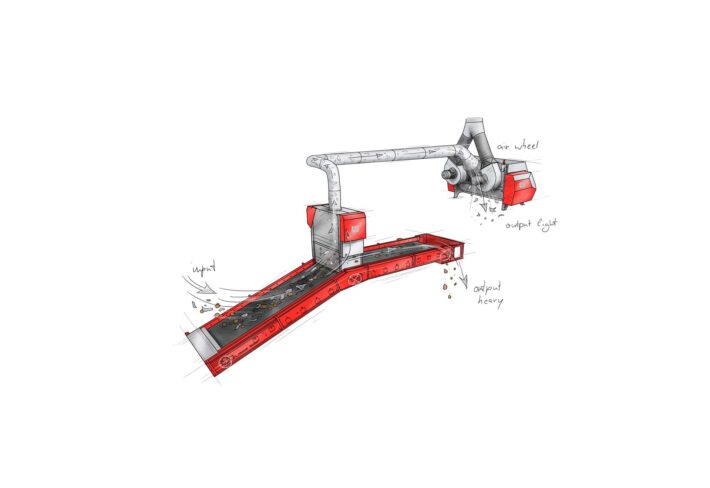

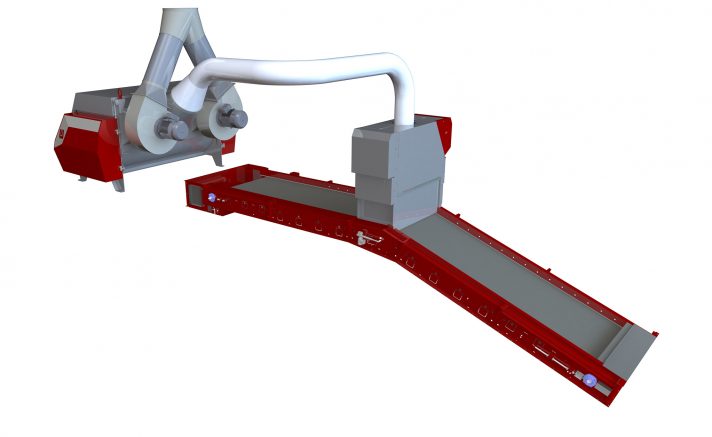

The AirLift system consists of the SpeedCon high-speed conveyor belt, the AirLift itself and the downstream AirWheel with integrated extractor fan.

The complete AirLift system (Figure 1) consists of three components. The SpeedCon high-speed conveyor belt, which has a particularly long design service life, feeds the material at up to 4 ms-1 to the central element, the AirLift (Figure 2), while the AirWheel is finally arranged downstream of the AirLift. Depending on model, possible working widths of the AirLift range between 1,000 mm and 3,500 mm, the widest being capable of handling throughputs of up to 320 m³/h with a grain size of 60 mm to 250 mm. Maximum outlet capacity is 5.6 t/h. Automatic gate controllers prevent material blockages on the input and the output sides and so ensure high operational reliability. Being continuously adjustable, such automatic gate control also ensures that the passage height can be exactly adjusted to the specific separation goal.

The SpeedCon is angled downwards by 20° directly below the intake. As a result, the air stream can more easily get underneath the light parts. Angling the conveyor in this way imparts a ballistic trajectory to all the input stream components to be sorted. The integrated controller can adjust the trajectory’s shape or throw distance via the belt speed and so tailor it precisely to the task in hand. Diametric downflow ensures particularly high selectivity. Levels of purity in excess of 95% are achievable depending on the input material. For instance, an analysis of AirLift systems installed in the mixed plastics feed to an NIR sorter revealed that, for a working width of 2,800 mm, over 90% of the desired film fraction could be reliably separated. As a result, the system considerably reduces disposal costs and so increases recycling cost-efficiency. Eliminating the film, which is usually located on top, from mixed plastics facilitates NIR sorting and distinctly improves the sorting result.

AirLift uses the diametric downflow principle in the settling chamber to ensure still more precise separation of the various fractions in a second stage. Operating parameters can be precisely adjusted using the integrated setpoint pressure controller.

System integration

The complete three-part AirLift system can be used as a sub-component of a more comprehensive sorting installation and its design means that, if needs be, it can straightforwardly be retrofitted.

Summary and outlook

Society is demanding that use be made of recycled plastics, a demand which policy makers are increasingly meeting. In the coming years, the circular economy will stop being a theoretical mission statement and become an everyday reality. Waste disposal operators already need high-performance sorting technology in order to be able to obtain optimally segregated secondary raw materials from the waste stream. High-quality recycled plastics are essential for manufacturing products which can be put to long-term use.

With AirLift in its range, Westeria has a solution which meets these requirements and can be straightforwardly retrofitted in existing sorting operations. The various models and configurations mean that it can be adapted to any kind of plant configuration. Westeria is constantly developing its technology and current projects include boosting the performance of its high-efficiency “DiscSpreader” material distribution systems, which are already well known to plant operators, by providing continuous readjustment on the basis of the actual distribution pattern.