PipeCon®

The PipeCon is an air-guided conveying system for any type of bulk material with precisely defined particle sizes, such as in the wood and cement industries.

-

Advantages

- High conveying capacity with up to 500 t/h

- Optional maintenance walkway possible as access to all relevant areas

- Reliable sealing system which prevents gravel leakage

PipeCon® PipeCon® PipeCon®

PipeCon®

Conveying materials with exact grain sizes

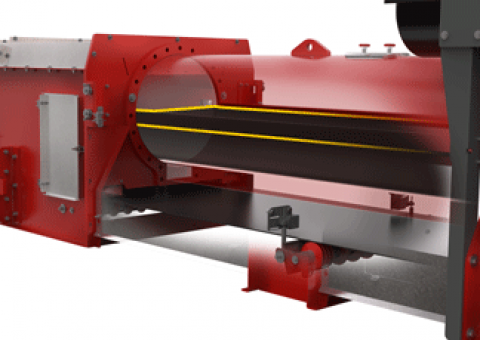

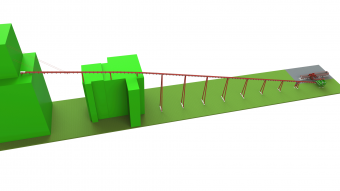

The PipeCon is a conveyor system designed for transporting bulk materials of all kinds over long distances. Extremely high conveying capacities (up to 500 t/h) are possible in the perfectly sealed pipe conveyor. The supports can be up to 60 m apart, with a total length of more than 300 m.

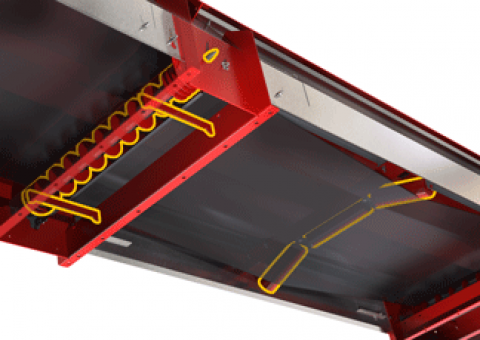

The belt floats on an air buffer generated by integrated fans. The 2.2 kW fans are located every 50 m at the top of the pipe conveyor. This drastically improves efficiency and minimises wear parts and maintenance of the machine. A maintenance walkway can be mounted directly on the belt, eliminating the need for an additional steel structure. The one-sided access is completely sufficient for full maintenance.

The tensioning station can be flexibly positioned on the floor so that the conveyor can be easily integrated into any plant design. In addition, a double scraper system is installed, which prevents uncontrolled falling of dust or trickling material. The PipeCon consists of 12 m long segments that can be quickly assembled. Due to our transport system, three of these segments can be safely transported and quickly unloaded in a 40′ containerert.

Optimally suited for outdoor use due to extremely good sealing.

Efficient and low maintenance

Return rollers

Walkway can be integrated

Simple maintenance

Most innovative conveyor

Dustproof

Highest efficiency

Walkway can be integrated

Simple assembly

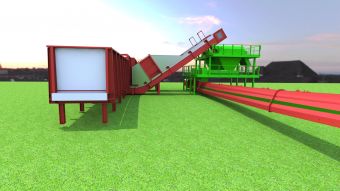

Feeding plant for the cement industry

Our engineers have developed a feeding concept for the cement industry that can be flexibly combined with Westeria’s standard solutions.

A complete system consisting of hopper (MovingFloor), chain belt conveyor (ChainCon) and PipeCon ensures a stable and uniform feeding of numerous input materials such as RDF, shredded tires or shredded waste. Optionally, a screen can also be easily integrated.

Further applications in the wood industry and recycling plants are possible.

All this makes it our most popular conveyor

in the cement industry.

Technical details

-

Frame construction

- Gurtbreite 1000 mm

- Diameter tube 660 mm

- Frame sections 11800 mm

- Bevel angle up to 20

-

Conveyor

- Conveyor belt according to DIN 22102

- Oil and grease-resistant / MOR

- Type Antistatic

- Belt width 1000 mm

-

Diameter drum

- Drive station 400 mm

- Clamping station 320 mm

-

Supports

- Positionable with up to 60 m distance

- Various column designs available as standard

-

One sided gangway

- Retrofittable as well

-

Weight tension station

- Flexible positioning on the floor

-

Fan performance

- 2.2 kW per 50 m conveyor distance

-

Access to maintenance

- Removable cover plates