MultiFeeder®

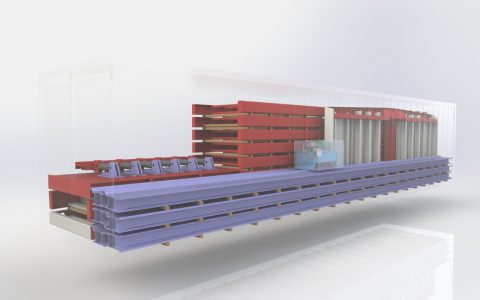

The MultiFeeder is a storage hopper system specially designed for fully automatic, linear distribution of input materials.

-

Advantages

- Space-saving and easy to integrate into existing plants

- Different floor designs: belt conveyor, apron conveyor or walking floor

- Shipping in standard sea containers thanks to modular design

MultiFeeder MultiFeeder MultiFeeder

Storage hopper system with linear distribution.

MultiFeeder is a storage hopper system specially designed for fully automatic, linear distribution of input materials.

It is space-saving and can be easily integrated into existing plants. It is the ideal starting point for material processing. For irregular material feeds, the MultiFeeder temporarily stores the material in the hopper and doses it evenly onto the next conveyor for maximum efficiency. Thanks to its easy-to-assemble modular design, it can be shipped in standard sea containers.

Flexibility in every detail

Modular

Quick assembly

Dimensions flexibility

Available in several different versions.

The MultiFeeder is available with four different bottom designs, depending on the metered material.

PlateCon

ChainCon

MovingFloor

BeltCon

Various fields of application

Thanks to the sophisticated modular principle, we can easily implement your specific requirements.

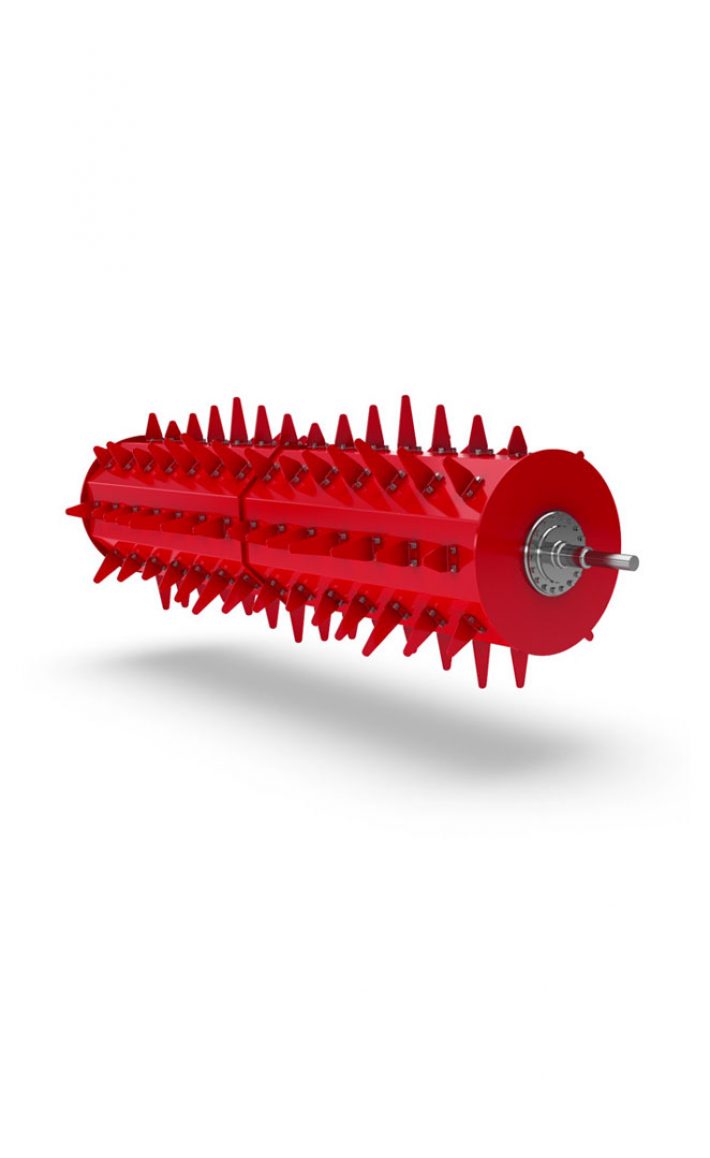

Equalising drum

A equalising drum can be added to ensure an extremely uniform material feed even with a full hopper load. The sealing system prevents material jams between the housing wall and the drum.

Size classification

Light: up to 0.3 t/m³

Medium: up to 0.6 t/m³

Heavy: up to 1.2 t/m³

Technical details

-

Hopper inside width

- 1566 mm

- 1866 mm

- 2266 mm

-

Hopper length

- 4455 mm

- 5940 mm

- 7425 mm

-

Support height

- 600 mm

- 800 mm

- 1000 mm

- 1200 mm

-

Belt width

- 1300 mm

- 1600 mm

- 2000 mm