MovingFloor®

The MovingFloor is a hopper system that allows you to dose any type of material and guarantee a smooth and continuous flow.

-

Advantages

- Modular construction

- Minimal wear

- Fast delivery

MovingFloor® MovingFloor® MovingFloor®

MovingFloor®

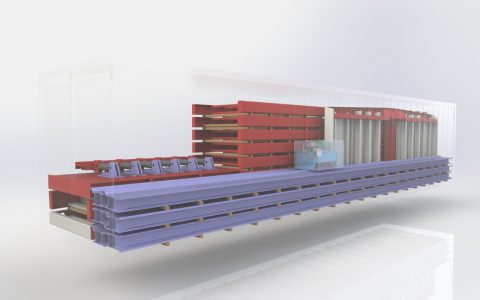

Bunker system with flexibility

Fully automatic material feed. Flexible configuration and quick delivery thanks to the modular system.

The feed hopper, which is technically sophisticated down to the last detail, offers maximum flexibility despite the use of standard components. The system is designed in such a way that the MovingFloor can be enlarged at any time and is capable of bunkering a wide variety of materials and feeding them evenly. Substitute fuels, compost, mixed construction waste and much more can be processed without any problems. The components can be delivered within 6 weeks and shipped in standard sea containers.

Flexibility down to the smallest detail

Modularity

Quick assembly

Simple maintenance

Westeria MovingFloor hopper system for

reliable and continuous flow of

of a wide variety of materials.

The MovingFloor is a hopper system that will help you dose any material flow. Materials can be loaded in a wide variety of ways. The integrated metering drum provides an even and continuous supply of material. A wide variety of materials can be handled, including refuse derived fuels, compost, mixed construction waste and more.

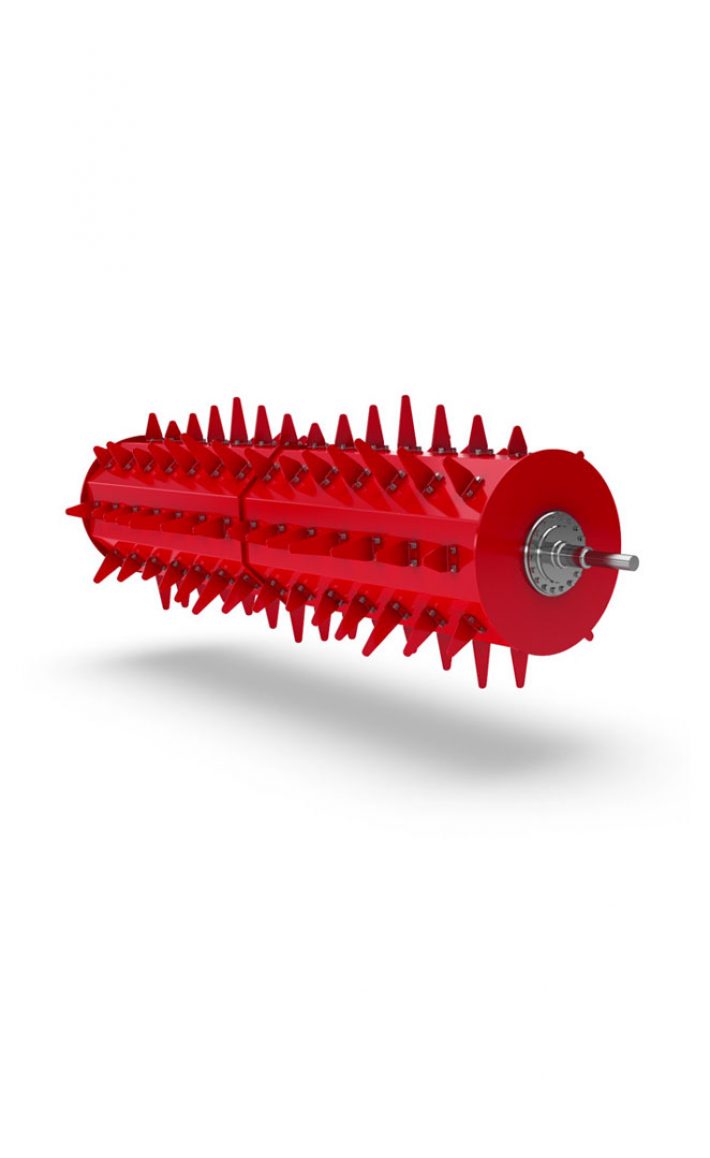

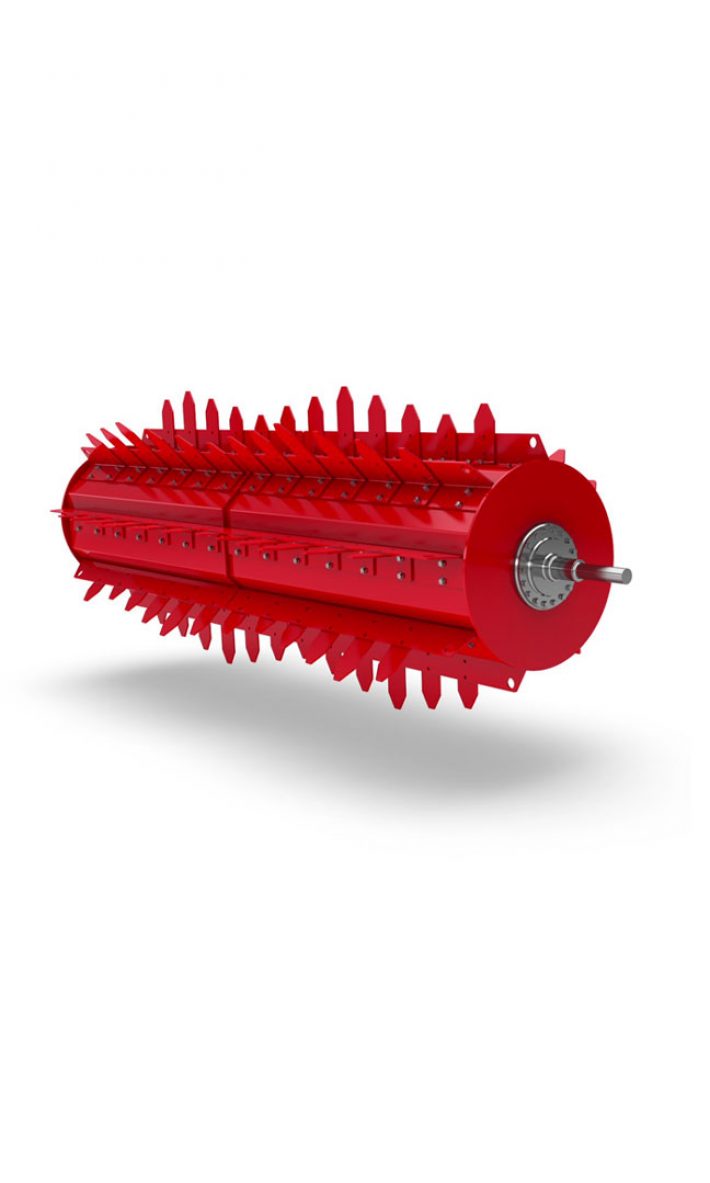

Hydraulic pistons

Light

Medium

Heavy

Features

To ensure a constant material supply even when the hopper is fully loaded, a compensating roller can be installed.

Its sealing system prevents material jams between the housing wall and the drum. The height of the rollers can be easily adjusted.

The technology can be integrated into existing concrete bunkers and ensures maximum efficiency of the connected sorting plants or incinerators.

Technical details

-

Volume

- 50 cbm

- 110 cbm

- 150 cbm

- 190 cbm

- 220 cbm

- 255 cbm

- 285 cbm

- 315 cbm

-

Bunker inner length

- 5540 mm

- 11480 mm

- 17420 mm

- 20390 mm

- 23360 mm

- 26330 mm

- 29300 mm

-

Hydraulic pistons

- Configurable with five different hydraulic cylinder pistons with different diameters

-

Modular principle

- Standard system from 20 m³ to 480 m³