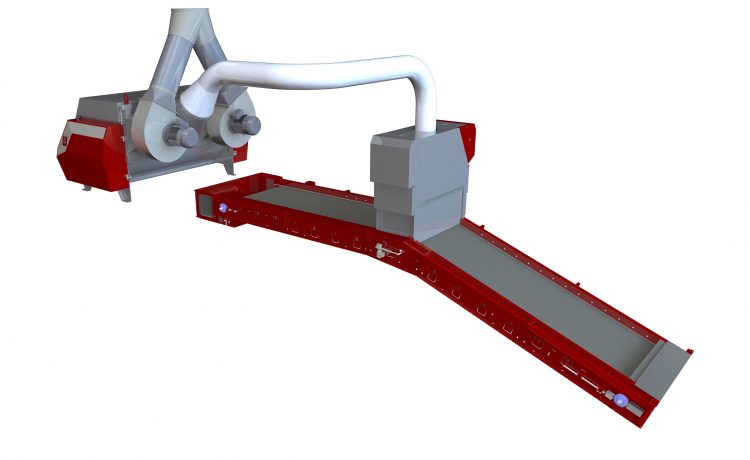

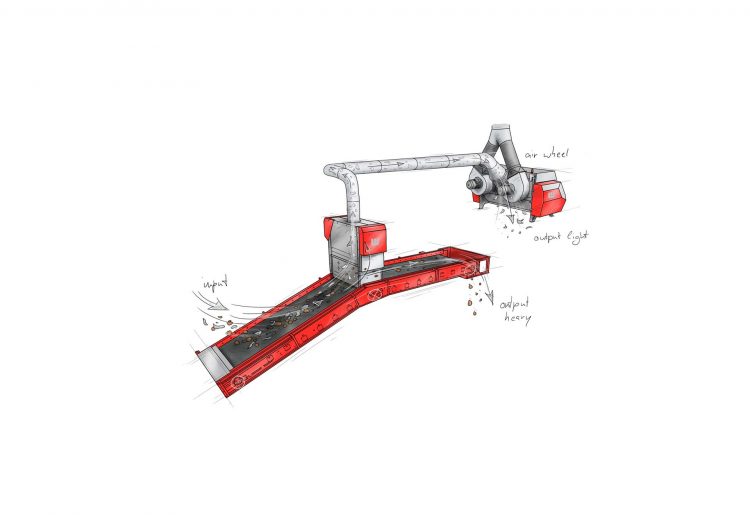

AirLift®

The AirLift separates what previously could not be separated. Materials with very similar specific densities are its specialty. This air classifier also ensures maximum efficiency when used upstream of the NIR classifier.

-

Advantages

- Higher efficiency than normal overband suction systems

- Precise adjustment of ballistic trajectory, air speed and visibility

- Purity levels up to over 99

- Max. Flow rate 320 m³/h

AirLift AirLift AirLift

Putting an end to nuisance

Air classifiers are a core element of systems for separating components of different weights contained in waste streams. Our AirLift vacuum air classifier is a particularly effective design.

The ultra-light separator enables sorting processes in which the specific weights and ballistic flight properties of the respective constituents differ only slightly. Applications include, for example, the recycling of PET bottles, where the valuable PET fraction can be cleaned with high efficiency and purity from light impurities such as labels made of PE film or paper. The AirLift also masters the great challenge of freeing biological waste from plastic contaminants outstandingly.

A windsifter system consisting of three components

AirLift®

AirWheel®

SpeedCon®

Stricter regulations require

sophisticated technologies

Ingenious technology down to the last detail

Separation of almost equal

weight materials

The AirLift separates what previously could not be separated.

Technical details

-

Wide

- 1000 mm

- 1500 mm

- 2000 mm

- 2500 mm

- 3000 mm

- 3500 mm

-

Max. Air volume

- 8000 m³/h

- 12000 m³/h

- 16000 m³/h

- 20000 m³/h

- 24000 m³/h

- 28000 m³/h

-

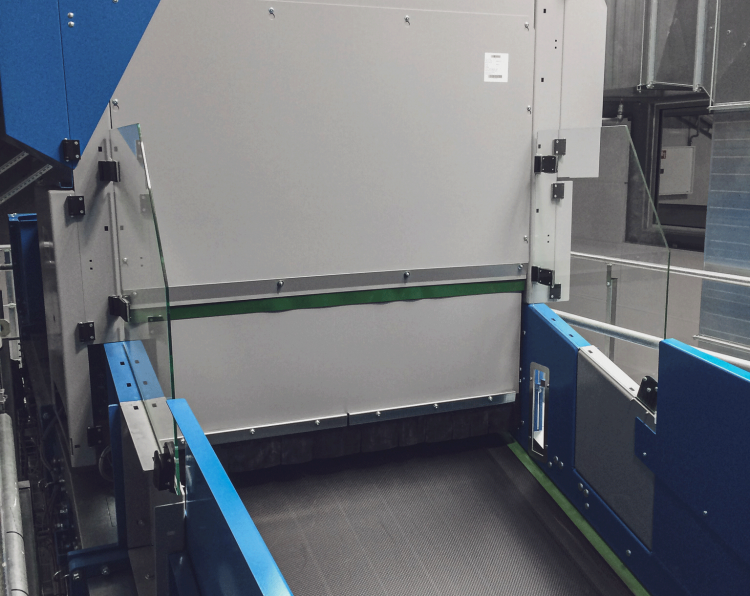

Conveyor belt designs

- +20°/0°

- 0°/-20°

- +15°/0°

- 0°/-15°

-

Optical sensors

- Material blockages are detected and solved by automatically raising the infeed and outfeed barriers