ChainCon®

The best chain belt conveyor you can find. With the complete redevelopment of our classic, we have not only integrated numerous technical advantages. As part of the WeKea system, there are a number of additional advantages for you.

-

Advantages

- Extremely robust and durable

- Maintenance made easy

- Quickly available and economical

ChainCon ChainCon ChainCon

The best chain belt conveyor you can find

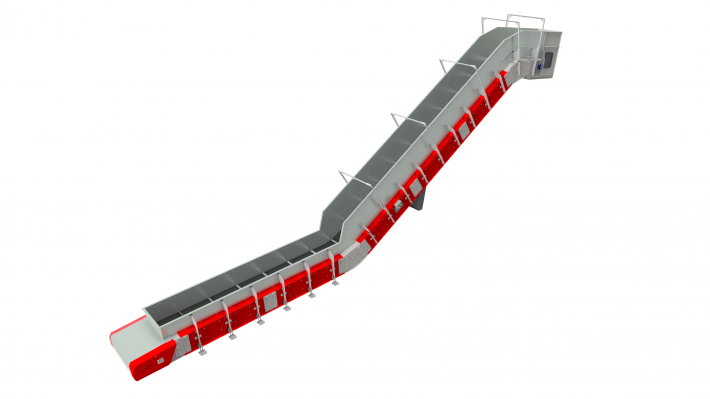

Westeria takes the chain belt conveyor to a new level. We have completely redesigned our classic to create the best chain-belt Z-conveyor you can find.

Feedback from our customers has resulted in a variety of ingenious technical innovations that make the conveyor a profitable, long-lasting machine. Reliability and the simplest maintenance are the key to smooth operation.

Of course, our chain belt conveyor can be flexibly configured. Up to a length of 35 m and belt widths between 1200 – 2400 mm, the ChainCon can be set up on the floor or in a pit.

The best chain belt conveyor on the market.

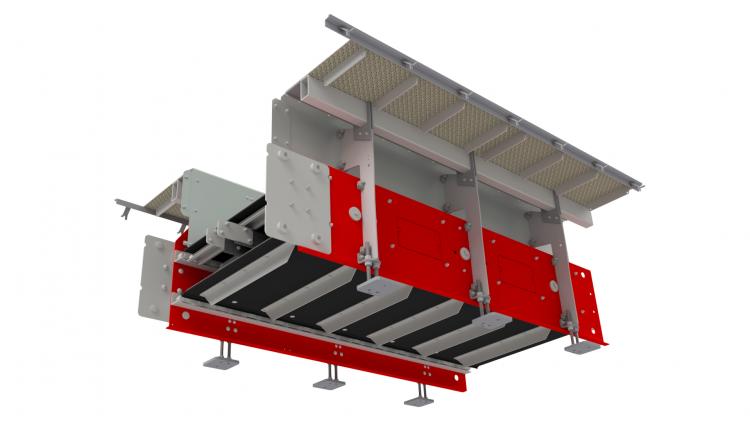

Robust like no other

Robust construction

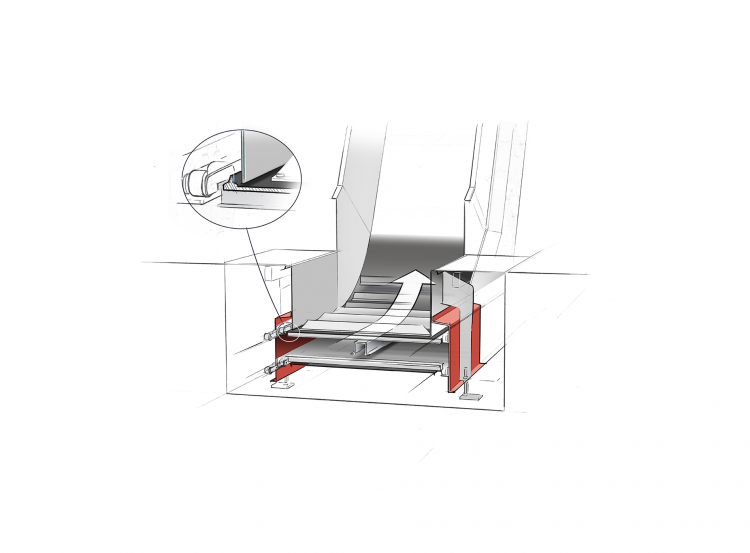

Intelligent impact concept

Solid chain-belt system

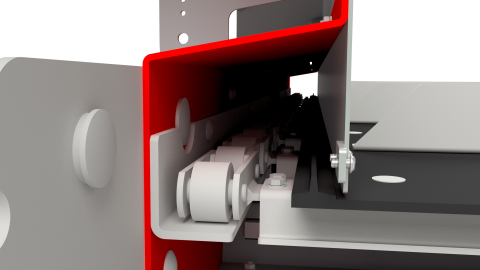

Chain guide for eternity

Sealing system

Simplest maintenance thanks to automatic chain lubrication

Materials

Technical details

-

Versions

- 2 bends (Z-conveyor)

- 1 bend

- No bend

-

Belt widths

- 1200 mm

- 1600 mm

- 2000 mm

- 2400 mm

-

Selectable incline after input

- 30°

- 35°

- 40°

- 60° (Tumble Back)

-

Selectable decline before output

- 0°

- -5°

- -10°

- -15°

- -20°

-

Centre distance

- Up to 35m in standard